Digital Fabrication and Robotics Lab

(FABLab)

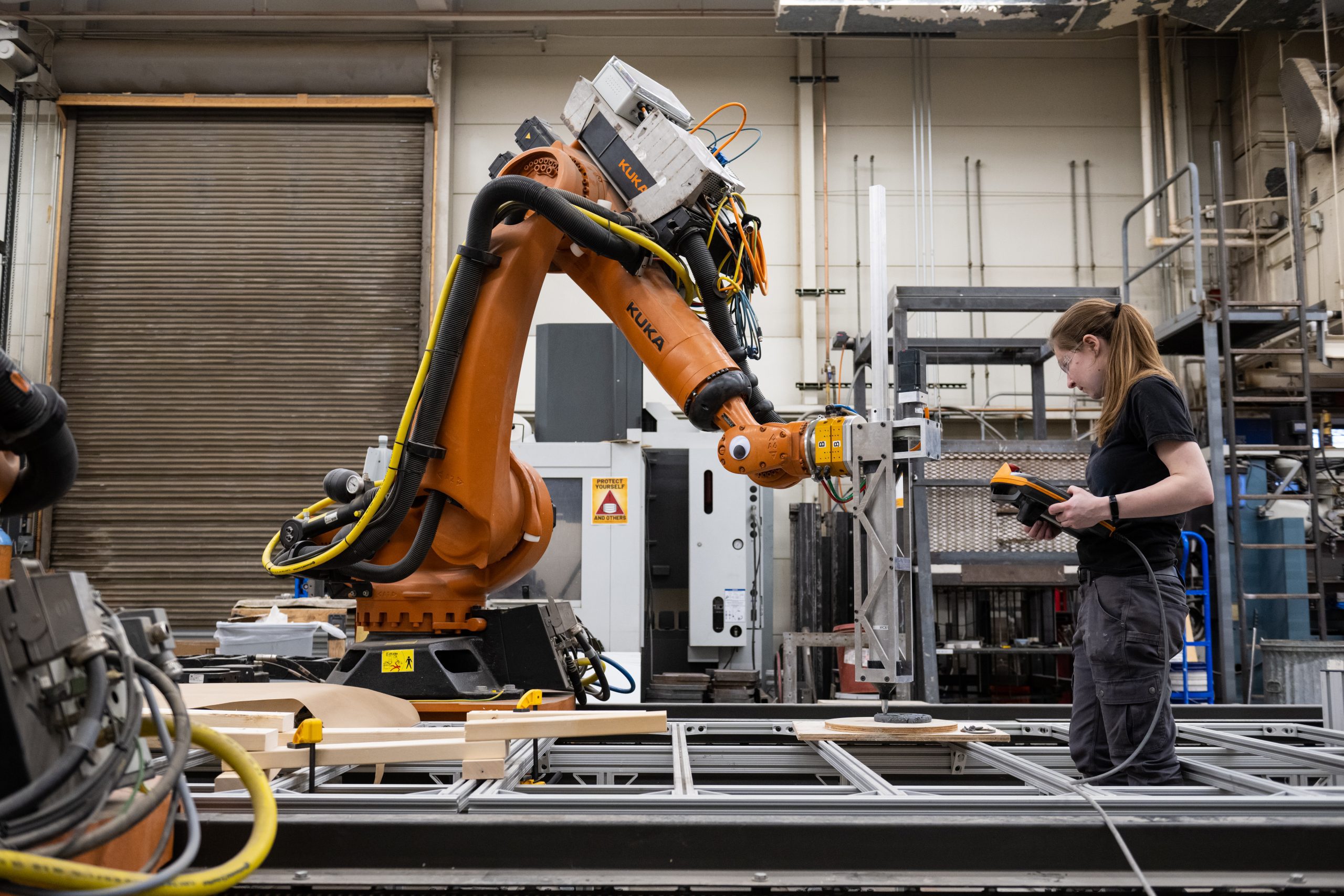

The Taubman College Digital Fabrication and Robotics Lab (FABLab) supports research and teaching activities in digital fabrication, robotic construction, and physical making across a wide range of materials and processes. It is recognized as one of the premier facilities among academic institutions worldwide.

The FABLab provides students and faculty at Taubman College with extensive access to industrial machinery and the expertise to apply it to real-world architecture and building construction challenges. The lab conducts fundamental and applied research with numerous industry partners and national funding institutions. The FABLab works with faculty and students on cutting-edge techniques that have the potential to transform practice in the fields of architecture, engineering, and construction. These efforts have resulted in the development of multiple novel fabrication processes, numerous patents, and an extensive number of built projects and publications.

About the Lab

Rooms

CNC Router Room

Located within the FABLab, these powerful machines are available to students and faculty. Each CNC has a functional bed size of six feet by eight feet. Materials commonly used include foam, MDF, or plywood. Thicker materials must be cut with a laser cutter. CNC router tools are optimized for particular applications on specific materials that may be found in the FABLab’s large inventory.

The FABLab sells limited MDF, LDF, Baltic Birch Plywood, and Polystyrene Foam supplies. There are also CNC coordinators available for consultation and walk-up file preparation/execution during their posted shifts.

Laser Cutter Room

Taubman College operates five laser cutter systems. Two LaserCAMM systems are in the woodshop on the first floor of the Art and Architecture Building, and three VLS 6.60 laser systems are in the west computer lounge on the third floor. These machines have 50-watt lasers with a working area of 32″ by 18″ (VLS) and 35″ by 20″ (CAMM). The laser can cut various materials, including most natural materials. A laser cutter’s power and speed settings must only be operated by Taubman students who have undergone training. Assistance is available throughout the week.

3D Printing Room

At Taubman College, four Stratasys 3D printers print in White ABS and Support material. Students can submit work from various 3D modeling software, such as Rhino, 3DS Max, Maya, and Fusion360. Each has a build volume of 10″x10″x10″. Print times can range from 1 hour up to 24 hours. After the print is complete, the structural support is removed by placing it in a chemical bath for around four to 12 hours, depending on the amount of support material. Assistants are available for consultation and walk-up file preparation/execution.

Knitting Machines Room

A CNC Knitting machine has a v-bed layout of 14 needles per inch, allowing for the knitting of multiple interconnected layers within a single seamless textile, producing the finest textiles. The design and production of textiles on the CNC Knitting Machine involves using STOLL’s proprietary software, M1Plus. Only designated students may operate this machine. Intensive workshops are also provided to students to introduce basic knitted textiles and machine knitting knowledge.

Equipment

In the Lab, students and faculty experiment and conduct research using an array of robotic and CNC equipment, including:

- 7 Kuka industrial robots

- 2 Universal robots

- 2 3-axis routers

- 1 5-axis router

- 1 3-axis vertical machining center for metals

- 1 3-axis waterjet

- 1 3-axis digital knife cutter

- 2 industrial CNC knitting machines

- Laser cutters

- 3D printers

These machines are supported by traditional metalworking tools, assembly areas, and collaborative teaching workspaces. Information about these machines and access can be found on the Taubman Intranet FABLab page.

Training

Students at all levels are trained to operate these machines through coursework, orientation sessions, and specific training sessions. The Lab also maintains a substantial staff of student technicians who are trained to operate machines, advise in fabrication techniques, and support the production of both faculty and student projects.

Ultimately, the goal of the Taubman Fabrication and Robotics Lab is to question how technology can contribute to a more sustainable, resilient, and equitable built environment. Architecture sits at the crossroads of engineering, design, and construction. How do we build tomorrow?