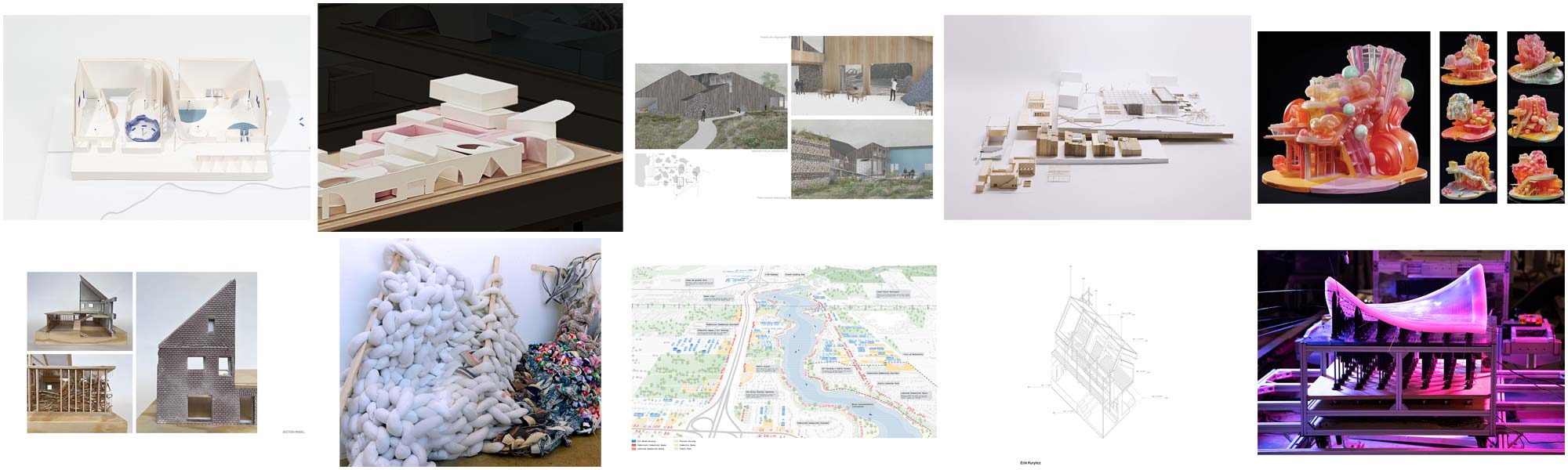

What materials and methods will allow us to design and construct low-carbon buildings? How can architects and designers promote social justice through community ownership of land? Through its Pressing Matters grant program, Taubman College has funded five faculty-led research and creative practice projects that address these questions.

“Backed by the breadth and depth of resources at the college and one of the nation’s top public research universities, our faculty and students are testing ways to limit anthropogenic climate change, promote human resilience in confronting it, and promote just outcomes and equitable flourishing in the built environment,” said Jonathan Massey, dean of Taubman College of Architecture and Urban Planning.

Taubman College supports many strategic initiatives that activate collaborations between experts from across the college and university, and from industry and community partners. Pressing Matters grant recipients collaborate with faculty from other disciplines, leading professionals, nonprofit organizations, and community representatives. Read more about the five funded projects below.

This year’s jurors were Ersela Kripa, associate vice provost for outreach and engagement, associate professor and the director of Texas Tech Huckabee College of Architecture – El Paso, and director of projects at the research center POST (Project for Operative Spatial Technologies); Marshall Brown, a licensed architect, urbanist, principal of Marshall Brown Projects, and associate professor with tenure at the Princeton University School of Architecture where he directs the Princeton Urban Imagination Center; and David Benjamin, founding principal of The Living, associate professor at the Columbia University Graduate School of Architecture, Planning and Preservation (GSAPP), and director of the GSAPP Incubator.

Intelligent Robotic 3D Concrete Printing for Lightweight Slab

U-M Research Team:

- Dr. Mania Aghaei Meibodi (PI), assistant professor of architecture

- Dr. Kira Barton (CoI), professor of robotics and mechanical engineering

Learn More

This research will develop Intelligent Robotic Non-Planar 3D Concrete Printing (NP-3DCP) to create ultra-lightweight slabs that require significantly less concrete than conventional construction and current 3DCP methods. Over the next 30 years, rapid urbanization will demand building homes and infrastructure for an additional 2.3 billion people. Effective construction methods are crucial to meet growing demands, especially considering the vital role of reinforced concrete structures in facilitating long-span construction. 3D Concrete Printing (3DCP) promises to meet this demand through digitizing concrete construction. Most 3DCP research has focused on compressive elements (e.g., walls, columns), neglecting tension-loaded elements like slabs, which constitute approximately 60% of a building’s total mass and have given no attention to material reduction in a part. This limitation stems from the prevalent method of planar 3D printing in 3DCP (P-3DCP), which restricts material deposition to horizontal layers and does not support the fabrication of structurally efficient forms that commonly entail complex geometries (i.e., extreme overhangs, ribbed geometries, branching structures).

The Role of Spatial Design for Community Land Trusts

U-M Research Team:

- Gabriel Cuéllar (PI), assistant professor of architecture

- Athar Mufreh (Co-PI), lecturer

Learn More

This project aims to document, synthesize, and disseminate the role of spatial design for community land trusts. Community land trusts (CLTs) are an essential tool in the struggle for affordable housing. However, the extent to which CLTs operate on a spatial level remains largely unconsidered. To date, architects have engaged with land trusts on relatively conventional terms, providing services to CLTs as normative clients. The spatial potential of CLTs, however, goes beyond housing. The community control of land is an opportunity to define and implement resident-led urban visions, which may include place-based reparative spatial justice, diverse housing futures, and broader urban and regulatory transformations. This project thus aims to, on one hand, document and learn from the work of established trusts already enacting such systemic change and, on the other, articulate the untapped potentials of spatial design for CLTs generally. The goal is to develop case studies and spatial strategies articulating the synergy of design and land trusts and deliver a practitioner-oriented resource guide that frames and demonstrates the urban and architectural potentials of CLT-driven urban transformations.

Community and expert partners:

- Rondo Community Land Trust, Saint Paul, MN

- Jeff Washburne, former Executive Director of City of Lakes Community Land Trust, Minneapolis, MN

- Dream Community Land Trust, Detroit, MI

- Ann Arbor Equitable Land Trust, Ann Arbor, MI

- Olivia R. Williams, Ph.D., Executive Director of Madison Area Community Land Trust

- Cassim Shepard, Distinguished Lecturer, City College of New York

Learn More

22/26 Midwest is based on research on the technology of the original 22/26 building conducted at the University of Michigan in recent years by the PI. The original 22/26 building located in Lustenau/Austria debuts an automated system of motorized natural ventilation control that obviate the need for active systems for heating, cooling, and mechanical ventilation. 22/26 Midwest builds on the technologies of the original 22/26 building and adapts them for the climate in the midwestern U.S.

Two research tasks are targeted:

Implementation of a novel plug-and-play predictive building automation system (Research Task I): The novel predictive building automation system in “22/26 Midwest” will enable the control of the thermal status of the building by predicting and controlling the interactions between thermal flow (between inside and outside) and the internal thermal/hydrodynamic capacity of the building. The building automation system will be based on an AI-generated algorithm.

Thermal and Hydrodynamic Capacity of Construction Materials (Research Task II): Other than in the climate in central Europe, buildings in the US Midwest have a relatively high energy demand for dehumidification in the summer. The hydrodynamic property of certain materials absorbs the humidity from the room air and therefore reduces the relative humidity of the air. 22/26 Midwest is investigating new ways natural materials can be used as a thermal and hydrodynamic buffer.

Partners:

- Steven Schenk (Co-PI), SchenkHattori Architects

- Shantonio Birch (Co-PI), ThermoVerse

Hygroscopic Envelope: Building enclosures for climate adaptation

U-M Research Team

- Tsz Yan Ng (PI), associate professor of architecture

- Evgueni Filipov, PhD (Co-PI), associate professor, civil and environmental engineering

Learn More

This project explores how 3D-printed ceramic facades can enable climate adaptation and resilience by collecting, retaining, and controlling the release of stormwater. The research seeks to extend lessons from Landscape-based Stormwater Management Practices (L-SWMPs), such as bioswales and other techniques for storing and infiltrating water, to the architectural facade. It advocates a paradigm shift for the building envelope, away from the conventional “rain screen” notion that facades must repel and shed water off the building, to one that directly engages and manages water in ways that benefit broader infrastructural and ecological systems that are vulnerable to the impacts of climate change. The research explores ways to alleviate the burden on municipal stormwater systems and the demand for intensive mechanical pumping systems that both consume significant amounts of energy and contribute to land subsidence over time. The work operates at three interrelated scales–the micro (material), the meso (component), and the macro (aggregated assembly)–to develop an integrated understanding of how material performance and the design of modular systems can beneficially interface with buildings, landscapes, and other stormwater infrastructures.

Partners:

- Elizabeth Camuti (Co-PI), assistant professor in landscape architecture

- Adam Marcus (Co-PI), associate professor of architecture

Functionally Graded Material: Performance Through Continuous Material Variation

U-M Research Team

- Wesley McGee (PI), associate professor of architecture

- Chinedum Okwudire (Co-PI), professor, mechanical engineering, integrative systems and design

- Rachael Henry (Co-PI), lecturer, architecture

- Alireza Fazel (Co-I), PhD student, architecture

Learn More

This research explores the emerging potential of functionally graded, multi-material additive manufacturing (FGAM) to produce high-performance, materially efficient building components. FGAM builds on the geometric freedom of typical 3D printing (3DP) processes by adding the capability to tailor material composition across a continuous component locally. In the context of architecture and construction, this local tailoring could address daylight or air transmission, as well as structural performance by creating building components with materials possessing tunable stiffness, such as fiber-reinforced composites. This proposal will explore novel techniques for material deposition and computational design, targeting the sustainable use of plastics in construction and addressing the challenges of material waste, mechanical strength, and environmental performance. The main objectives include optimizing geometry and material performance for both structural integrity and passive solar thermal control, establishing a robust design framework for functionally graded materials, and evaluating the effectiveness of FGAM through structural tests. The overall goal of the FGAM approach is to reduce material waste while matching or exceeding existing performance criteria. The research methodology involves the development of novel hardware and software tools for large-scale polymer additive manufacturing utilizing a dual-screw pellet extrusion system for the precise deposition of multiple materials and a computational design framework for optimizing the variation in material properties across a component. The team will conduct prototyping studies to calibrate design and process parameters, followed by mechanical testing for compression and tension strength. Collaboration across the disciplines of architecture, material science, and engineering is a key element of this research. The expected outcomes of this research are prototypes and test results showcasing the capabilities of FGAM, laying the groundwork for further external research funding and industry collaborations.