Ng: Using Digital Fabrication to Drive Innovation

Digital fabrication has great potential for driving innovation in building materials, construction processes, and manufactured products, says Tsz Yan Ng, an assistant professor of architecture.

To realize that potential, she is pursuing material-based research and design ― with a special focus on textile manipulation and experimental concrete forming ― at Taubman College’s FABLab, a preeminent facility for architecture fabrication research.

“We are incorporating contemporary technologies that allow us to develop new ways to build better products and to manufacture things that will be more responsive to our environment,” Ng explains. “We are also considering issues of crafting that we haven’t thought about previously in using these new technologies.”

The concept of sartorial architecture ― which she developed for her research and teaching ― centers on the allied discipline between architecture and clothing manufacturing. Both industries are highly complex global phenomena that depend upon manufacturing. But they also require an understanding of how technology, human labor, and socio-political forces all come into play.

The two industries frequently borrow techniques from one another, says Ng. In the clothing business, for example, patterning is used to make three-dimensional garments out of two-dimensional cloth. In the architecture field, the same thinking applies to developable surfaces (i.e., shapes that a flat sheet can take without tearing or stretching), which allow architects to create three-dimensional objects from two-dimensional materials.

Ng’s personal experiences laid the groundwork for her current research endeavors. She grew up in the clothing industry, where her mother was a seamstress and her father worked for the New York-based fashion label Lafayette 148 New York. She studied architecture in college and received her Master of Architecture II from Cornell University.

Ng’s background and professional world intersected in 2005 when the CEO of Lafayette 148 New York commissioned her to design the company’s new 11-story headquarters building in Shantou, China, to house its manufacturing facility, offices, and showroom. The concrete structure, completed in 2010, features a post-tensioning system that provides an extended, unbroken span on each floor for flexible factory arrangements. It also has a specially engineered brise-soleil façade that serves as a sunscreen and works with other passive cooling strategies to bring light and air into the core of the building.

“It wasn’t until I worked on this design project, after getting my architecture training, that I made the connection between these two industries ― architecture and clothing manufacturing,” Ng says. “This project spawned my work for the next 10 years.”

At the FABLab, Ng’s research reflects her idea of bringing together the soft (textiles) and the hard (concrete) in innovative ways that enhance design capabilities while considering the intellectual and physical labor of crafting.

For a project involving thermoplastic concrete casting, Ng uses the sartorial techniques of tailoring and patterning to cut and felt together synthetic-fiber material. Once shaped, the material is heat stiffened to create an open three-dimensional formwork. The mold is then sprayed with a thin layer of glass-fiber reinforced concrete (GFRC). This project is intended to create complex surfaces for large-scale GFRC casting using as little material as possible while retaining structural properties.

“The textiles are patterned into 3D forms in much the same way that cloth is patterned into garments in clothing manufacturing,” Ng says. “So, there is a strong connection between the technique and the material in how the hard and soft are coming together.”

For another project, Ng is collaborating with an expert in computer numeric control (CNC) knitting and an engineer to make specialized (functionally graded) knits that can be used as formwork for casting concrete. Designs are programmed into a CNC knitting machine, which produces the desired quality of polyester or elastic monofilament knits. The knitted material is configured into formwork, which is then cast with concrete. After the concrete hardens, the knitted material can be removed or left in place.

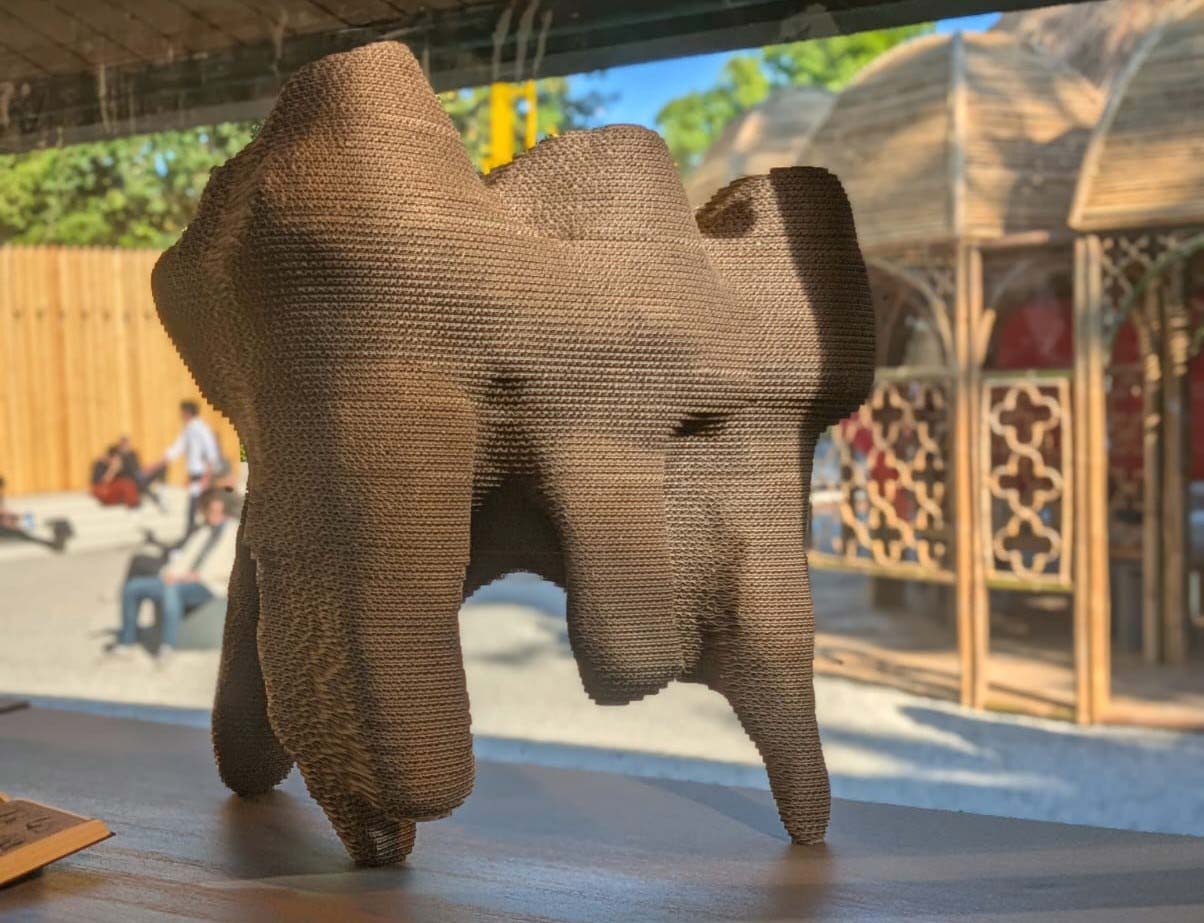

In her research, Ng is utilizing advanced technologies to transform time- and labor-intensive processes, such as artisanal felting, which traditionally has been done by hand. One such advance is robotic needle felting, which uses a robotically controlled system with barbed needles to punch through layers of wool or polyester nonwoven textile. This digital fabrication process allows Ng and her collaborator, a roboticist, to experiment with additive manufacturing techniques by layering the textile into 3D forms to manufacture acoustic panels and furnishings.

In a recent project, Ng and the FABLab’s director, Wes McGee, are partnering with Victor Li, a materials scientist and professor in U-M’s College of Engineering, to develop 3D printing processes for using Li’s specialized formulated concrete. This technique potentially could give architects greater design flexibility while eliminating the use of casting molds and manual labor commonly associated with concrete construction.

Ng’s research work also is enriching the curriculum for graduate students in her year-long Thesis course.

“The students experiment extensively with concrete forming using various digital fabrication tools and linking these material-based investigations with computational design in the FABLab,” she says. “This experience will prepare them to go into practice, because digital fabrication is going to have a huge impact on the types of design the next generation will create.”

― Claudia Capos