Meredith Miller, associate professor of architecture and director of the masters of architecture program, and Thom Moran, associate professor of architecture, are principal investigators, and Chris Humphrey, FabLab associate manager and lecturer in architecture, is a research coordinator on a project awarded a 2-year National Science Foundation (NSF) Grant. The funding will support their proposal, “Using waste plastics from regional manufacturing to create new building material.”

The National Science Foundation returned their application with detailed feedback the previous year and encouraged the team to revise and reapply.

“When we got the funding, it was a sigh of relief. Now we can do the work that we really want to do and feel a little more validated,” Meredith Miller said.

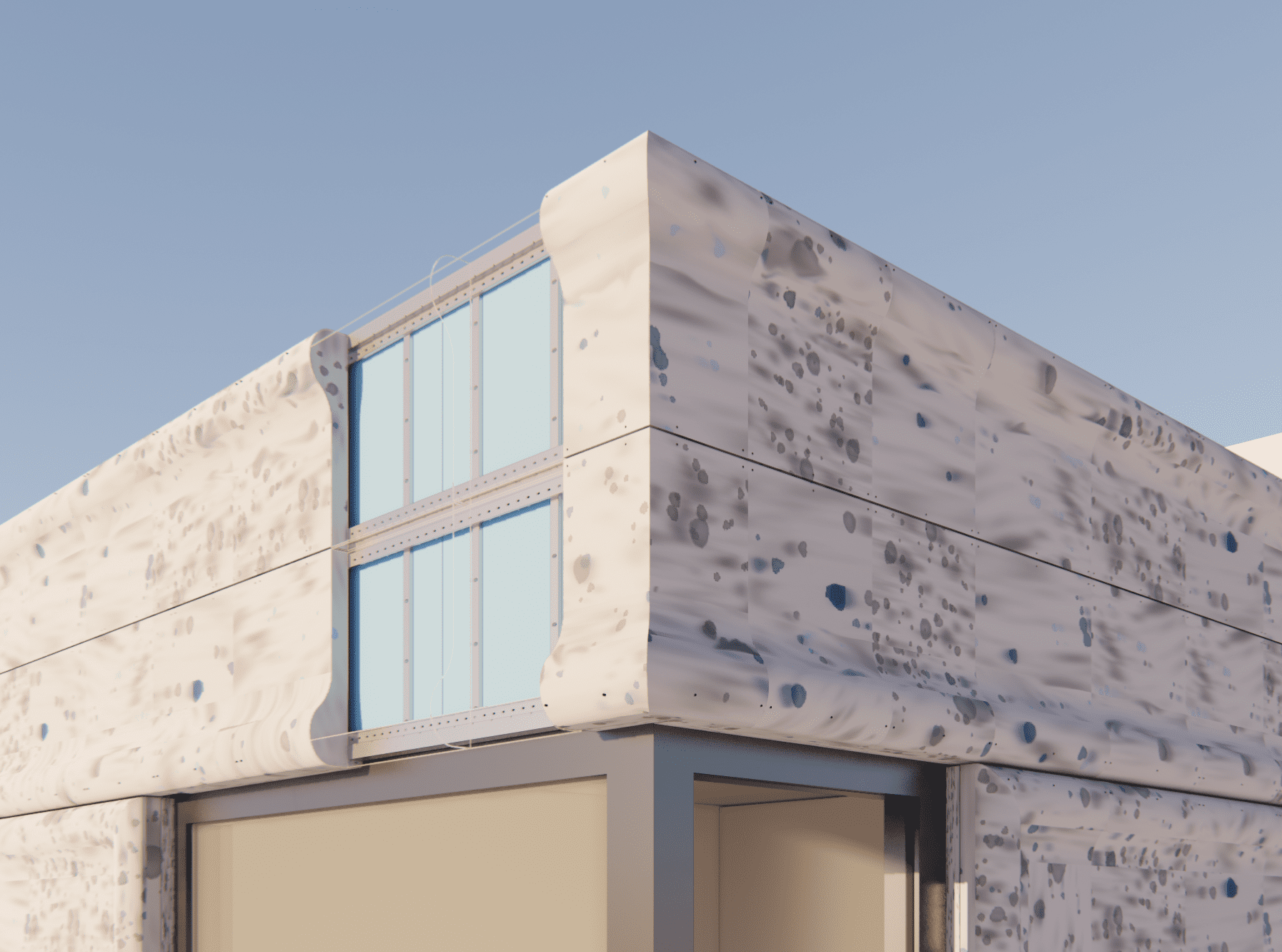

The grant will support their ongoing efforts to commercialize Post Rock, their patented technology for creating a cladding material from waste plastics. The project has consulting support from OSU’s Center for Design and Manufacturing Excellence and Fire Assembly Engineer Nicholas Dembsey.

The research team says they “will assess the viability of using waste plastics from regional automakers and other manufacturers as feedstock for their product. Working toward a durable and aesthetic facade material, testing and evaluation will focus on flammability, UV resistance, strength, and other criteria.”

This design-informed material research project aims to be the only composite product in the U.S. cladding market with a high level of recycled polymer content and aesthetic variation. The ongoing project focuses material research development toward a specific end use with its next step being commercialization. Post Rock has already endured two intensive phases of customer discovery, and with this grant, they can begin establishing a regional supply of source material. Utilizing new applications that add value to upstream waste materials and capture carbon in long-lasting products will create a more circular economy. Additionally, this poses a new strategy to combat climate change through architectural systems.

“There’s an opportunity for architects and designers to have more say or be more involved in what materials are going into buildings,” said Miller. “The way our profession often works is that we specify materials that are already out there, and most building materials are industrialized products. Right now, the whole field — and the world — is becoming more aware of the carbon intensity of construction. So, this project has been about whether we can develop a product that goes beyond what we might do as individual researchers and asks if we can develop a product that many people can buy and specify in their buildings.”

This project is far from over. The team will move forward with commercialization after eight years of hard work. “I continue to learn new things through this project, and it moved me to realms that I wasn’t familiar with before, like talking to people in the building industry or learning about entrepreneurship…these are things I wasn’t expecting to get into, but Post Rock led me there,” said Miller.