Robotic Needle Felting

Published:

06/28/2025

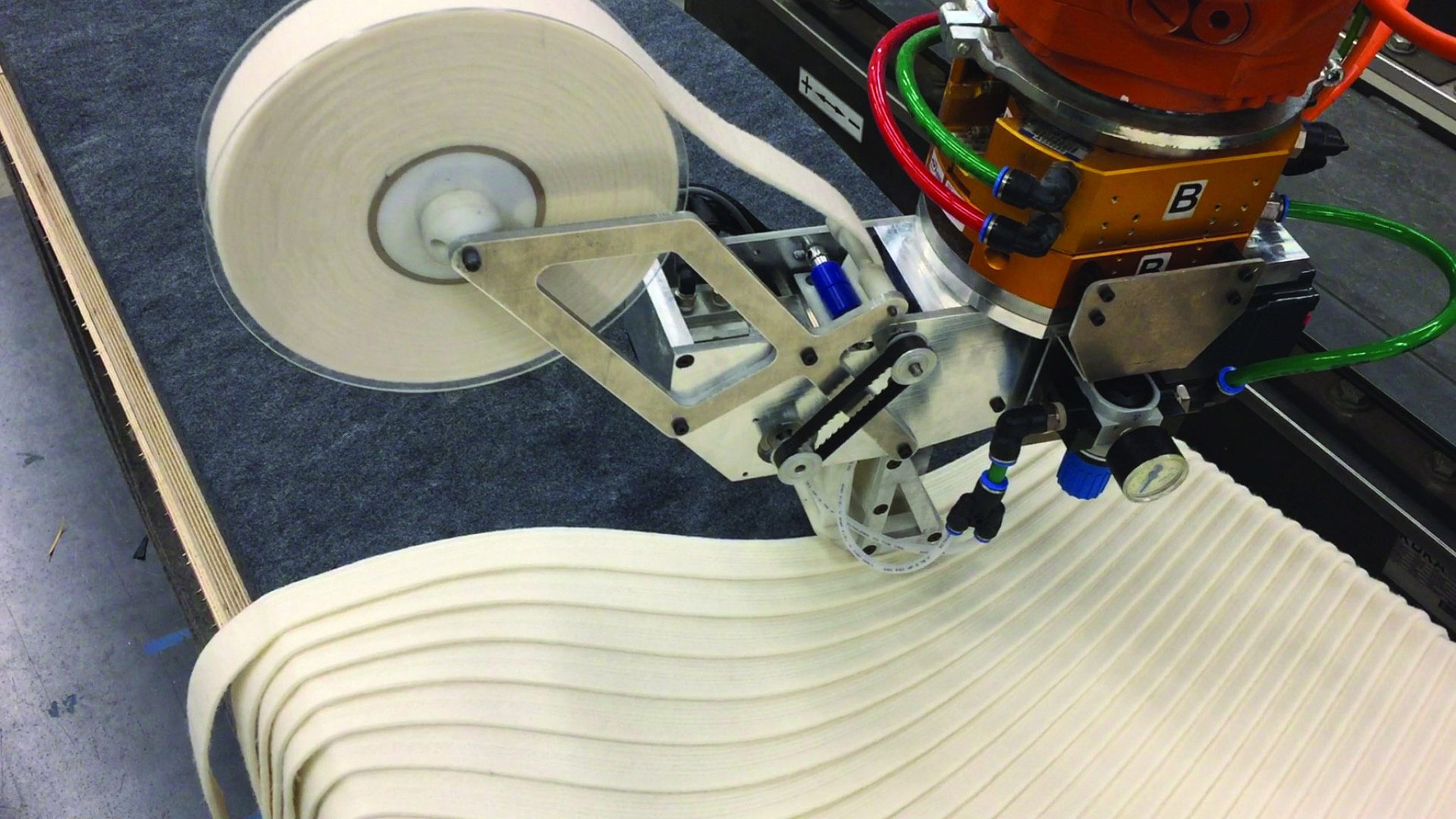

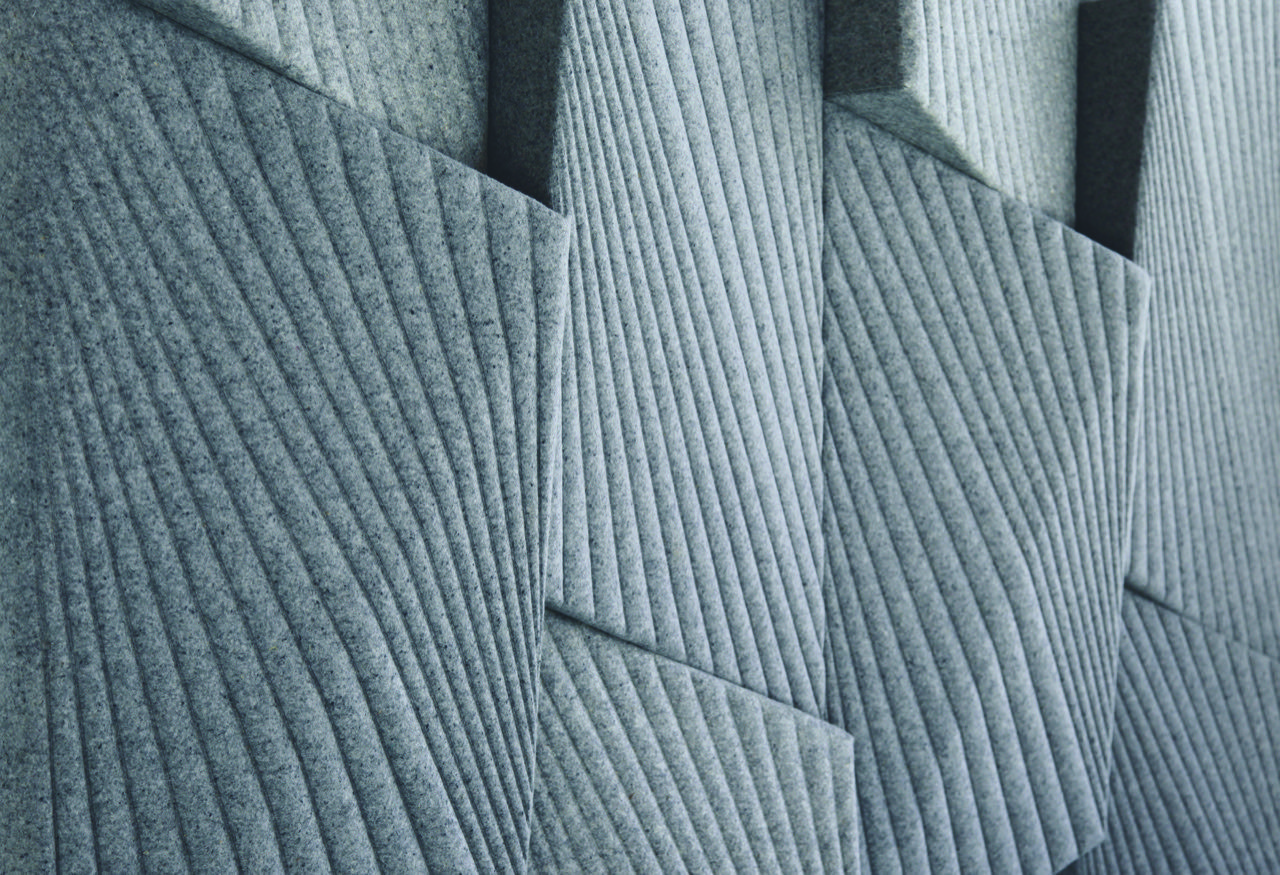

Robotic Needle Felting is a novel additive manufacturing technique for nonwoven textiles. Ng, McGee, and Peller considered how the traditional process of needle felting—where a barbed needle pushes through layers of fabric and, as it pulls back, entwines the threads and thus the layers to unite the plies—could be integrated with robotic manufacturing to create a more efficient way to bind thermoplastic textiles. The result, which the team developed by using Taubman College’s Digital Fabrication Lab, is an additive process somewhat analogous to 3D printing: A robotic head equipped with a needle is fed a strip of felt that it then lays out and attaches onto a foam substrate, as can be seen in the below video. Integration into a robotic process not only enables precision and speed in manufacturing but also extends needle felting as a 3D process, especially for surfaces with complex geometries.

Seven Taubman College Faculty Win R+D Awards

3D printing meets felt in new additive manufacturing technique

Research Through Making 2018: HARD + SOFT: ROBOTIC NEEDLE FELTING FOR NONWOVEN TEXTILES

Faculty:

Tsz Yan Ng

Wesley McGee