SHELL WALL: Coupling Non-Planar Robotic 3D Concrete Printing and Topology Optimisation

Published:

03/10/2023

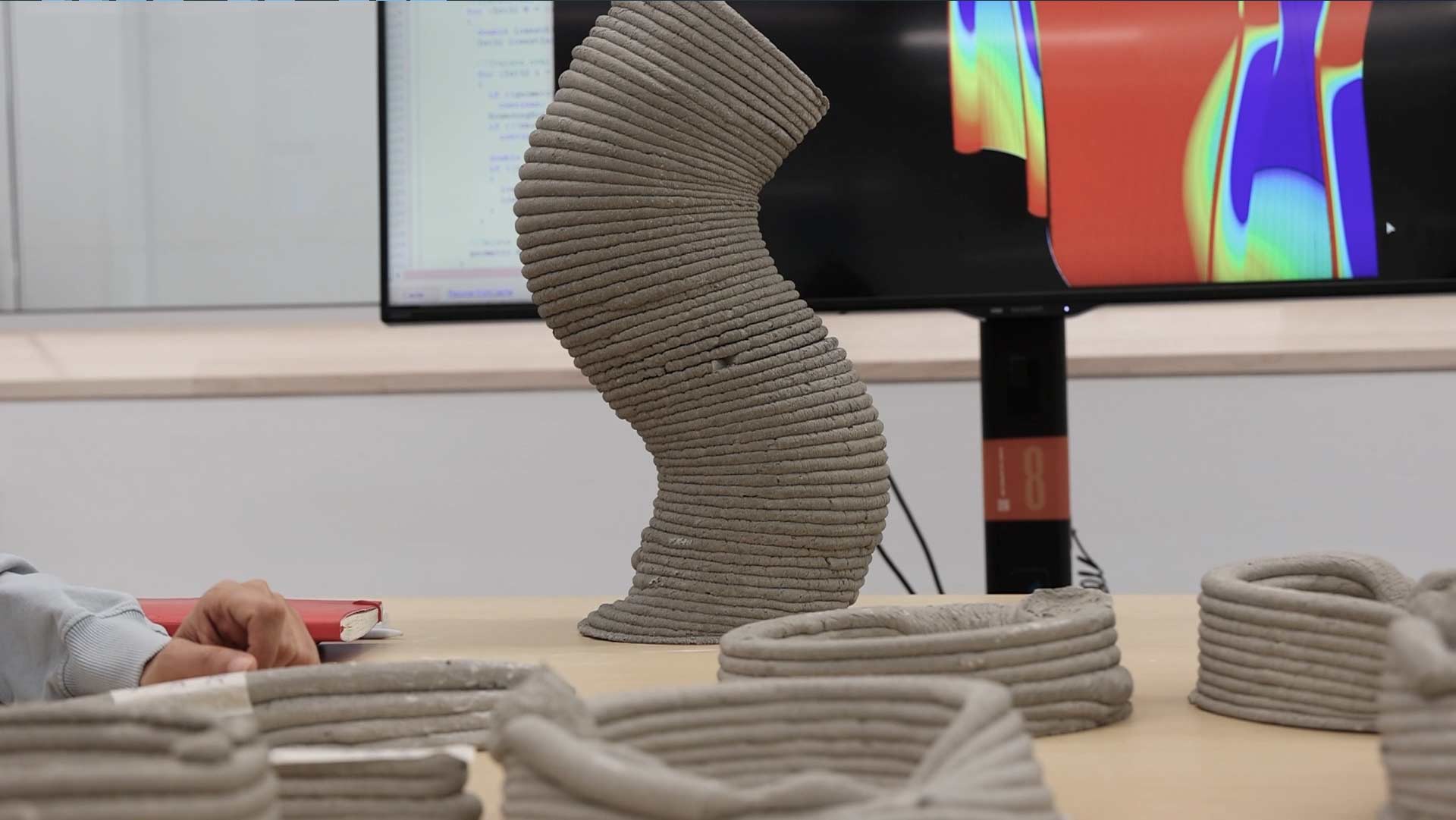

Prof. Mania Aghaei Meibodi, director of the DART laboratory, and her team made a groundbreaking advance in 3D concrete printing for construction by developing a method for creating ultra-lightweight, freeform reinforced concrete building elements. The team created a computational model that synergizes non-planar and variable material deposition based on the shape and geometric features of the topology-optimized parts. One of the advanced features of that model is the ability to regenerate forms to closely match the initial optimization while taking into account any fabrication and material constraints. The model automatically generates data for 3D printing, non-planner tool paths, and variable material extrusion rates.

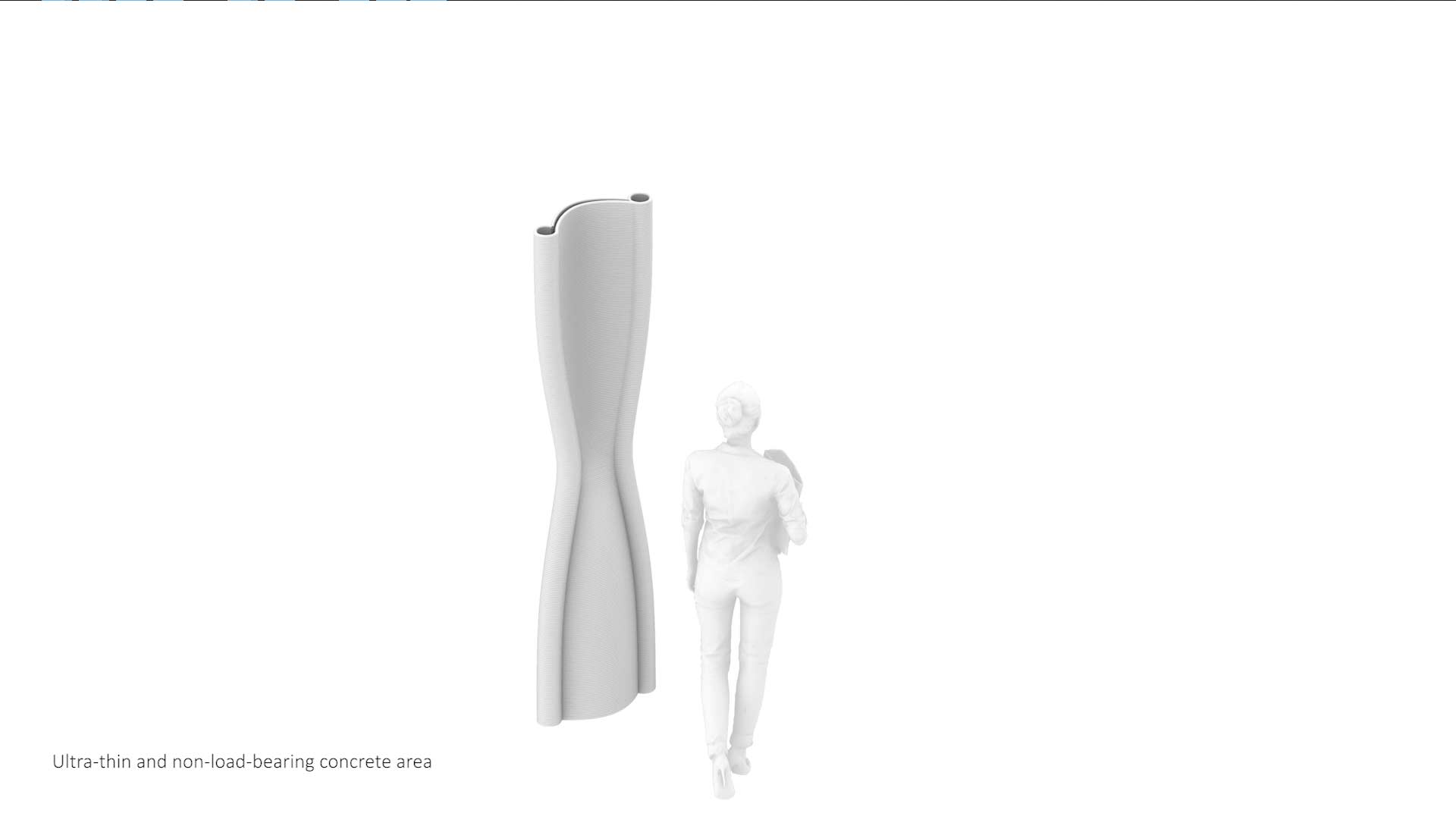

Shell Wall demonstrator is the first lightweight, structurally reinforced freeform concrete wall ever 3D printed. This innovative wall system features a geometry optimized to support its load case, with material distributed in a hierarchical grid of curved ribs ranging in diameter from 65 to 150 millimeters. The non-load-bearing areas between these ribs are just 6.5 to 8 centimeters deep, enabling the sandwiching of insulation between two concrete shells that are only 2.5 millimeters thick. The fields of concrete between the ribs are domed to increase stability and minimize material usage. Shell Wall weighs only 160 kilograms – a 72% reduction in weight compared to a conventional, solid concrete wall of equivalent size.

DART’s innovative 3D printing method allows for waste-free concrete construction and efficient use of material by placing it precisely where it’s needed for structural purposes. DART’s 3D printing method also facilitates the practical implementation of 3D concrete printing by using commonly available concrete rather than relying on highly specialized mixes. Shell Wall demonstrator uses a significantly smaller amount of concrete and rebar than the much larger quantities that would typically be required for a wall of the same dimensions. Additionally, DART developed a lightweight and affordable 3D concrete printing system for Shell Wall to increase accessibility.

Acknowledgments

Project Team

- Prof. Dr. Mania Aghaei Meibodi, director of the DART laboratory at the University of Michigan

- Alireza Bayramvand, Researcher at the DART laboratory

- Yuxin Lin, Researcher at the DART laboratory

Industrial Partner: Eco Material Technologies

Faculty:

Mania Aghaei Meibodi

Cynthia Pachikara