Through tectonics the architect may make visible, in a strong statement, that intensified kind of experience of reality which is the artist’s domain.

In 2009, under the deanship of Monica Ponce de Leon, the Taubman College of Architecture + Urban Planning awarded the first five Research Through Making (RTM) grants, an internal competition aiming to seed-fund faculty research. A decade of yearly awards has since passed, defining not only an entirely unprecedented model for the development of design research, but also a set of early 21st-century architectural questions and concerns that permeate through this body of award-winning work. Collectively considered, commonalities are apparent across these projects. Constrained by a fixed budget ($20,000), and complemented by the resources offered by the college (the FabLab, student participation), the work encompasses one-to-one scaled installations, experimentations with digital fabrication, innovative material reassemblies, and the conception of architectural prototypes. Categories of projects, too, emerge from the collection. Material ones are perhaps most apparent: concrete (Catenary Concrete Funicular Formwork, Thermoplastic Concrete Casting), wood (Limb), glass (Storm Glass, Glass Cast), clay (Dirty Work, Elemental | Ornamental), carbon fiber (Carbon Fiber Architecture), plaster (Morphaux), bioplastics ((De)Composing Territory), thatch (Hair, Spikes, Cattail, and Turkeyfoot), even pure H20 (Electrofrost). The projects can also be categorized according to processes of assembly: folding (Crease, Fold, Pour, Deploy: Spatial Patterns of Lightweight Landscapes), casting (RoboPinch, Thermoplastic Concrete Casting), knitting (Knit Architectures, Social Sensory Surfaces), and CNC routing (The Stratus Project, Texture Tectonic), But maybe more fundamental to research in architecture, as a discipline that extends beyond material studies and construction technology into the aestheticized world of symbols, the work can be categorized per the basic elements of architecture: vaults (Re:Vault, C-Lith, Shadow Pavilion), skins (The Aurora Project, The Stratus Project, Ana-Log Cabin, Resonant Chamber), or as will be explored in the following discussion, tiles.

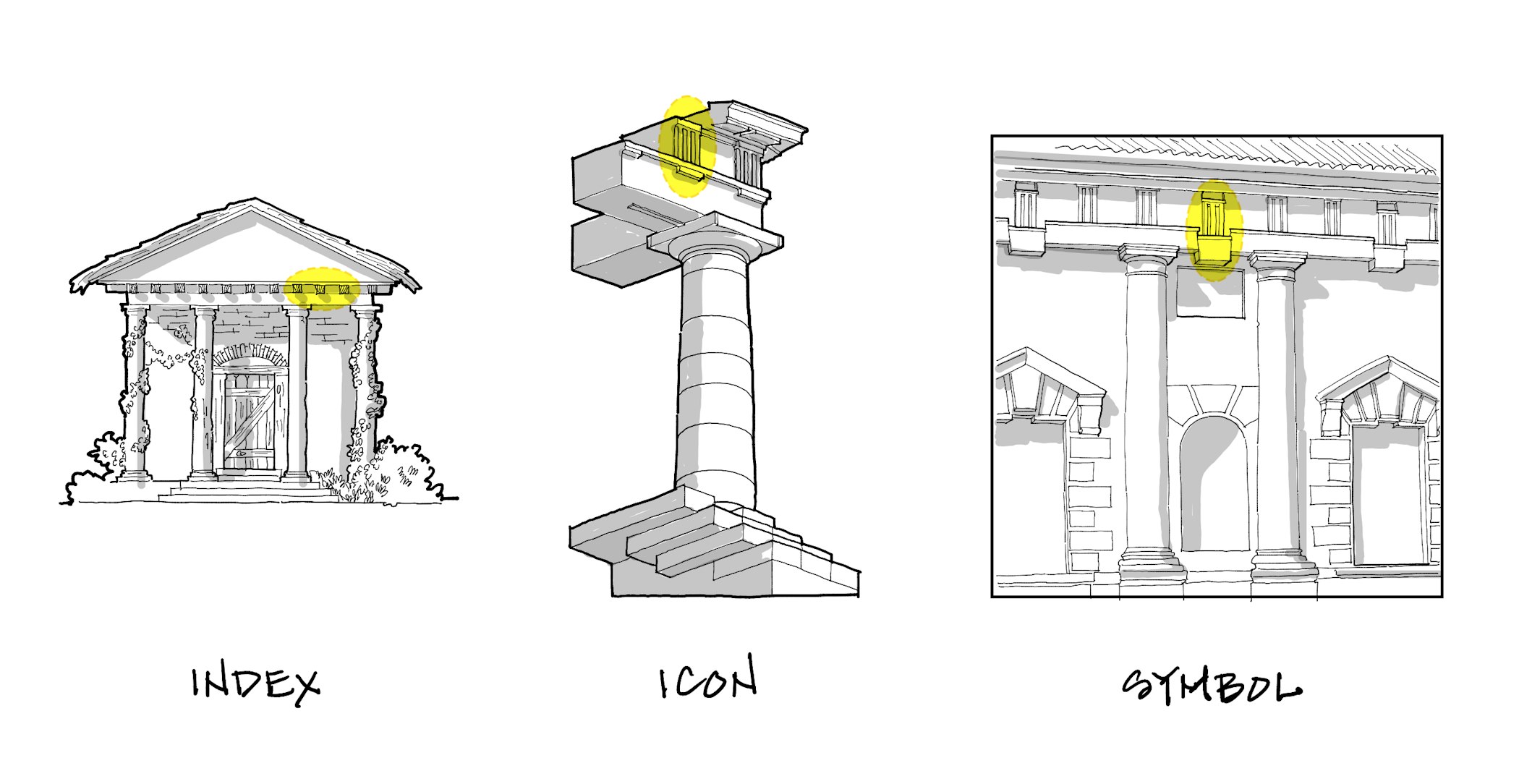

Architectural ornaments, such as tile, are inevitably functional in origin—a concealment modernism sought to make explicit by exposing building elements in their least decorative, albeit often aestheticized, forms. For example, the vertical end-grain of rafters on primitive structures indexed wood’s non-homogeneous structural capacity. These were later expressed iconically as marble triglyphs on the frieze of temple entablatures. Furthermore, extracted from their context and dropped from the entablature (as seen on Romano’s Palazzo del Tè) they became symbolic ornaments, an intentional “making strange” that enhanced their legibility by making them non-functional—the sort of Brechtian Verfremdungseffeckt much beloved by postmodernist / deconstructivist architects. Not surprisingly, we recognize here Charles S. Peirce’s three categories of signs in increasing culturally coded order, the indexical sign being the most universally accessible [Fig. 1].

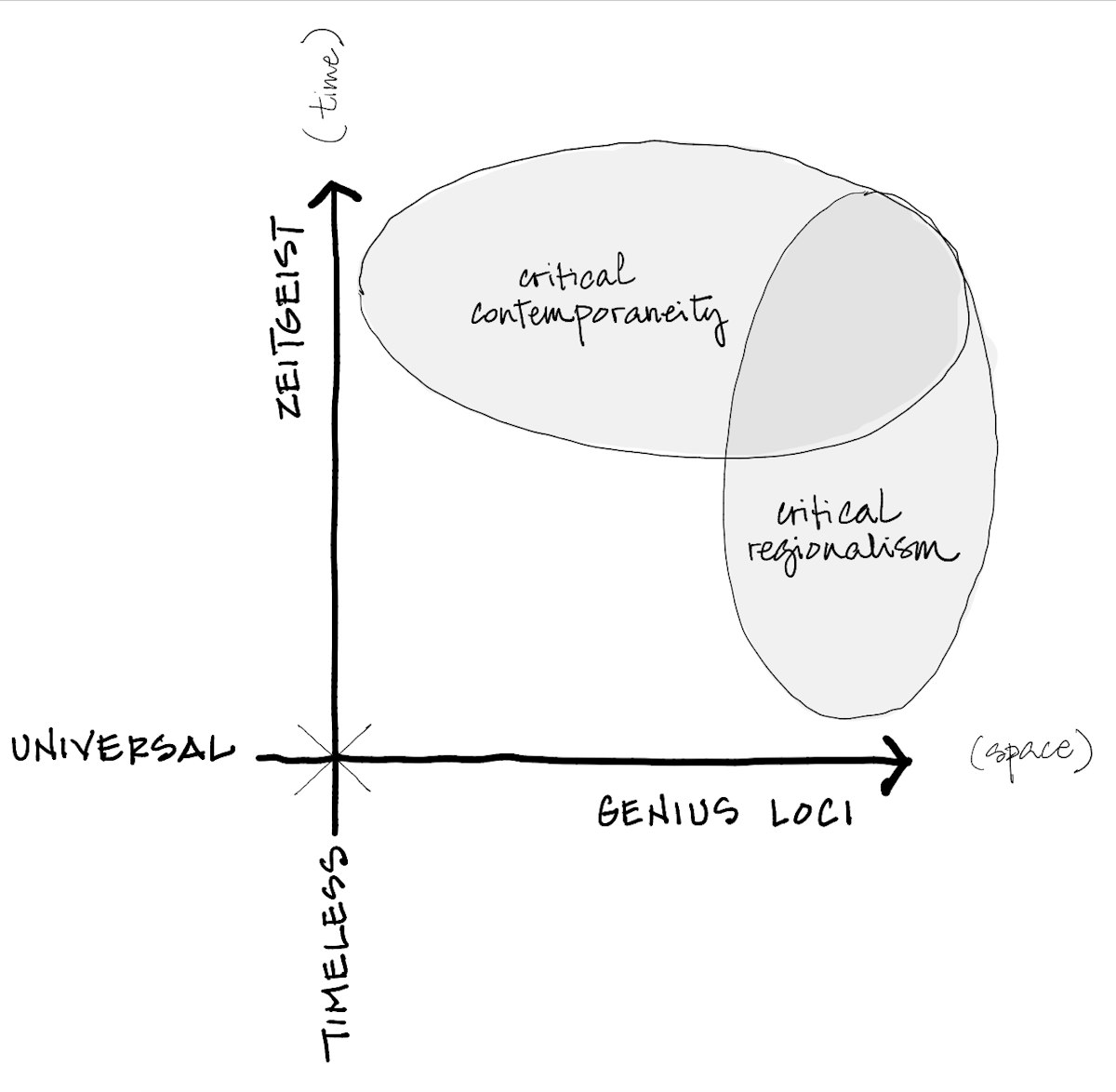

Whether we are analyzing triglyphs or tiles, other building elements or assembly of parts, we can read architectural tectonics as such signs, inexorably shifting from the indexical to the symbolic according to two axes that respectively track time and space. The first ranges across a spectrum from a “timeless” architecture to “high-tech” aesthetics that situate a building at the specific time of its construction, its zeitgeist or spirit of the time; the other from a “universal” architecture—a deliberately “international style”—to a site-specific construct that aims to capture its genius loci, or spirit of the place. Crossing these two axes offers a spatio-temporal framework for reading architecture [Fig. 2]. If the lower left quadrant aspires to tap into a universal and inclusive aesthetic experience, and one can locate Frampton’s points for critical regionalism on the right-hand side, the upper half could benefit from an equivalent theory for “critical contemporaneity”. An architecture that prototypes cutting-edge technologies most blatantly manifests a period’s zeitgeist, as the projects discussed below beautifully illustrate. The question of “to what ends?” seems imperative: after all, the deliberate formal expression of a zeitgeist quickly loses its status as avant-garde exemplar to become an archival artifact. Far from the timeless, such forms move from the contemporary to the dated as rapidly as our computers’ OS updates. If we avoid a short-sighted commitment to technology for technology’s sake but understand it as instrumental, the question of its end-goal remains a work in progress which falls within the impetus behind the Research Through Making program: for example, what new applications can a seven-axis Kuka robot offer? But if automated fabrication tool acquisition was an effective means to render the program competitive and raise enrolment, faculty winning R&D awards seems an equally befitting pursuit—even if the question of ends remains.

[Fig. 1] Examples of triglyphs as Indexical, Iconic, or Symbolic forms, illustrating C.S. Peirce's categories of signs according to increasing cultural mediation. (After William Chambers, Auguste Choisy, and Giulio Romano.)

[Fig. 2] Graphs locating tectonic forms from a universal space-time origin point towards increasing space-time specificity.

[Fig. 3] Encaustic tile fabrication process. © Morcillo Pallares Rule

The following projects, all variations on the basic element tile, denote cultural and historical specificity despite their universal use. While tiles invariably provide permeability, insulation, acoustic resonance or absorption, the aesthetic treatment of their materiality denotes specificity. A rather minimal building fragment, tiles embody a full story that comments on culture and place (space) as much as on technology (time). The Research Through Making projects below take it upon themselves to critically highlight the use of technology not as a requisite process but as a means to attain heretofore unexplored ends by reviving traditional ways of making. Hydraulic pressing, electroforming, and felting are revisited through these projects as practices that invariably render the tiles to which they are applied “of their time.”

In Panots & Mosaics: The Plasticity of Hydraulic Cement Through Making, Ana Morcillo Pallares and John Rule probe the encaustic cement tiles as a starting point. A 19th-century Catalonian typology, the handmade cement tiles offered cheaper and stronger floor and wall tiling than their handmade glazed ceramic counterparts. At the turn of the 20th-century, the fast-pace urbanization of Barcelona generated intense mud slides during rainy days.[1] The city tackled the issue by giving each homeowner the responsibility to pave two and a half meters in front of their properties. The city provided the materials, turning to the cement tiles, or panots, as an ideal, affordable, yet decorative solution. A choice of five patterns selected as the outcome of a 1907 competition standardized the options. Multiple axes of symmetry in the motifs enabled an easy and flexible system to produce and repair, and the depth of the grooves served to retain water, making them less slippery on rainy days. If the panots have become symbolic of the city, especially those portraying the iconic flor de Barcelona, they originated as a rainwater overflow management solution, and as such, indexed the time and place of their origin.

Morcillo Pallares + Rule (MPR) revive the panot into the 21st century by first combining it with another cement compacted typology, the encaustic tile, introducing the possibility for adding inlaid color to the originally embossed patterns [Fig. 3].[2] They then identify original limitations dictated upon both panots and encaustic tiles (mosaics): the structural capacity of the original cement necessitated a weighty 2cm thickness for a 20 x 20cm tile; the rigidity of the molds (Trepa) constrained them to a flat surface. Utilizing a glass fiber reinforced concrete mix containing plasticizer, the MPR tiles not only become larger, thinner, and lighter (achieving structural strength at a 5mm thickness for a 60 × 60cm tile), but the cement mix also allows for distortion [Fig. 4]. Creating a pliable formwork digitally distorted to any desired geometry enables these thin tiles to form a controlled topographic surface embedded with color [fig. 5]. Finally, exchanging the Modernismo patterns of early 20th-century Catalonia for the more abstract signature variations of Josef Albers’ iconic “Homage to the Square” situates the tiles into the cultural realm of American academic studies, rendering the MPR tiles a pure product of their place and time [Figs. 6 & 7].

[Fig. 4] Trepa over pliable formwork © Morcillo Pallares Rule

[Fig. 5] Controlled topographic surface © Morcillo Pallares Rule

[Fig. 6] Finished 5mm thick cement tile © Morcillo Pallares Rule

[Fig. 7] Exhibition installation © Morcillo Pallares Rule

In a similar vein, Akoaki’s Electroform(alism): Masters, substrates and the rules of attraction begins with locally-sourced material—metals harvested from Detroit’s glut of demolition debris [Fig. 8]—and hybridizes 19th-century plating techniques with digital technology to produce short runs of cheaply mass-produced ornamental tiles. First exploited under Czar Nicholas to match the Russian taste for baroque ornamentation, the process of “electroforming” long offered low-cost access to bling.[3] The process is simple: a substrate made conductive with a thin layer of graphite (cathode) is suspended together in an electrolyte solution with the harvested metal source (anode). The discharge of an electrical current activates the transfer of the metal onto the substrate at the molecular scale. The longer the electro-deposition process lasts, the thicker the coating layer [Fig. 9]. The method thrived on 19th-century tastes for affordable surface beauty, but with the rise of Modernist austerity and subsequent rejection of cheap ornament, the majority of electroforming applications were relegated to the military industry, whose manufacturing facilities were largely located in Detroit. One can thereby locate both materials and ways of making as specific to South-East Michigan, rendering the tiles place specific.

[Fig. 8] Roof of Packard Automotive Plant in Detroit. The site served as a research instigation for the Electroform(alism) project in its concern with post-modern landscapes, unofficialized labor, and the flux of building materials © Akoaki

[Fig. 9] Copper electroplating bath slow cooking tile with disposable mold. © Akoaki

Their coupling however indexes current practices, both economically and aesthetically. On the one hand, we can recognize in the short run manufacturing the city’s legacy of small-scale economically generative production. Akoaki’s project begins with the design of a compact mobile manufacturing laboratory, derived from the self-constraint of a 99¢ per tile output [Fig. 10]. On the other hand, if the electroforming process derived from a desire to mass-produce perfect replicas, Akoaki appropriates it to match a contemporary longing for variations and difference, combining the auratic value of artisanal craft with automated fabrication: each tile configuration is repeated but not mass-produced. Differentiations are generated in two ways: a three-fold rotational symmetry pattern made of clusters of three interlocking tiles necessitates identical footprints but offers the possibility for discrete topographies. The vacuum formed styrene plates molded from an assortment of CNC milled medium density fiber board offer indefinite variations on the topography of the assembled pieces. To add further singularization, the metallic tiles are individually weathered through a range of different oxidation times, resulting in endless shades of patina [Fig. 11]. Once again, the final product is uniquely situated not only geographically but also historically: it features our early 21st-century market-aesthetics’ appropriation of the recycled, the vintage, the vernacular, or the bespoke—a trend that coincides with the economic downturn’s longing for authenticity [Figs. 12 & 13].

[Fig. 10] Electroform(alism) deployable fabrication unit © Architect Magazine

[Fig. 11] Electroform(alism) tiles patina sample © Akoaki

[Fig. 12] Electroform(alism) exhibit at La Placette, Lausanne, Switzerland, 2014 © La Placette

[Fig. 14] Electroform(alism) exhibit at Liberty Annex, Ann Arbor, MI 2014 © Akoaki

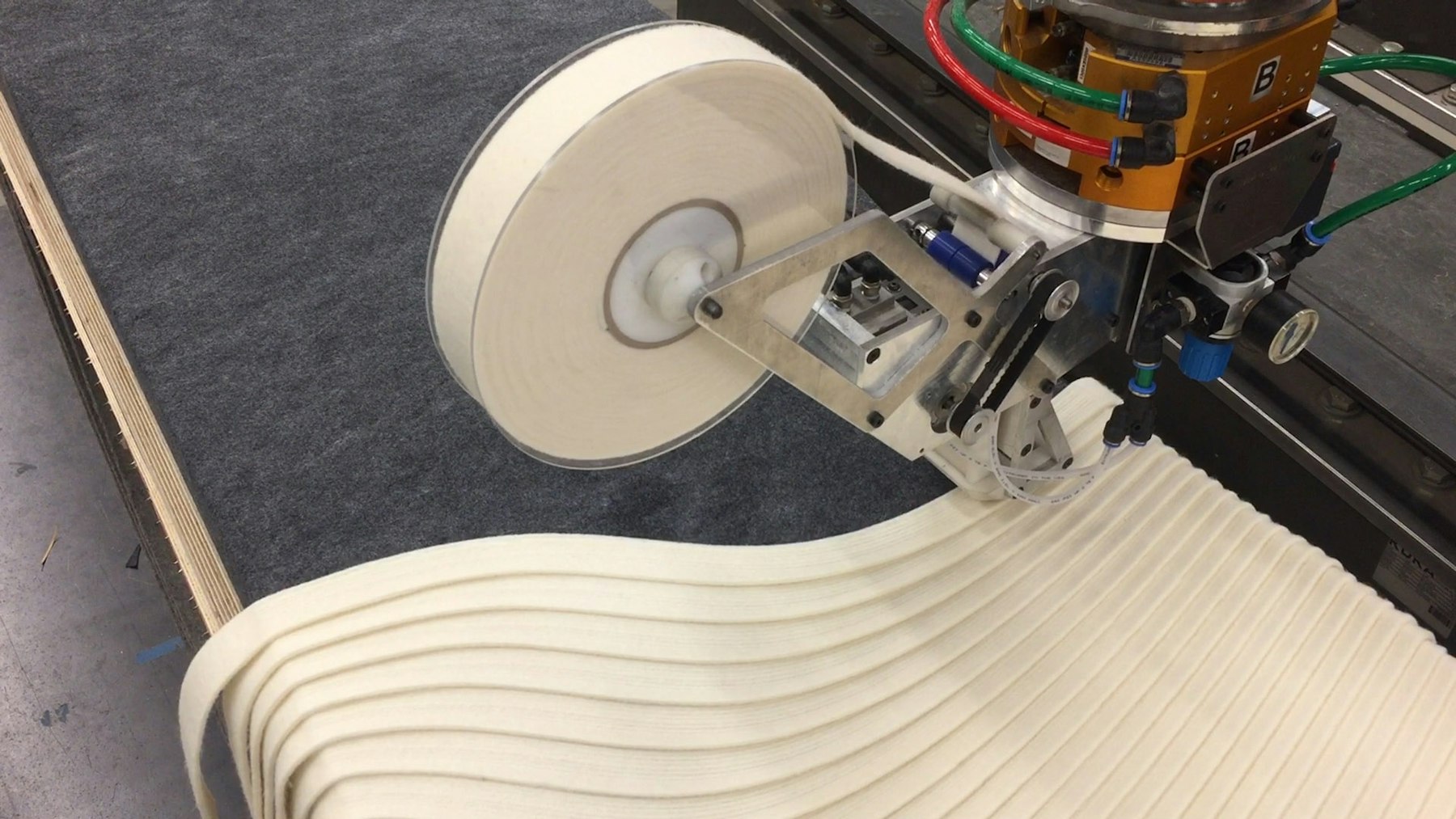

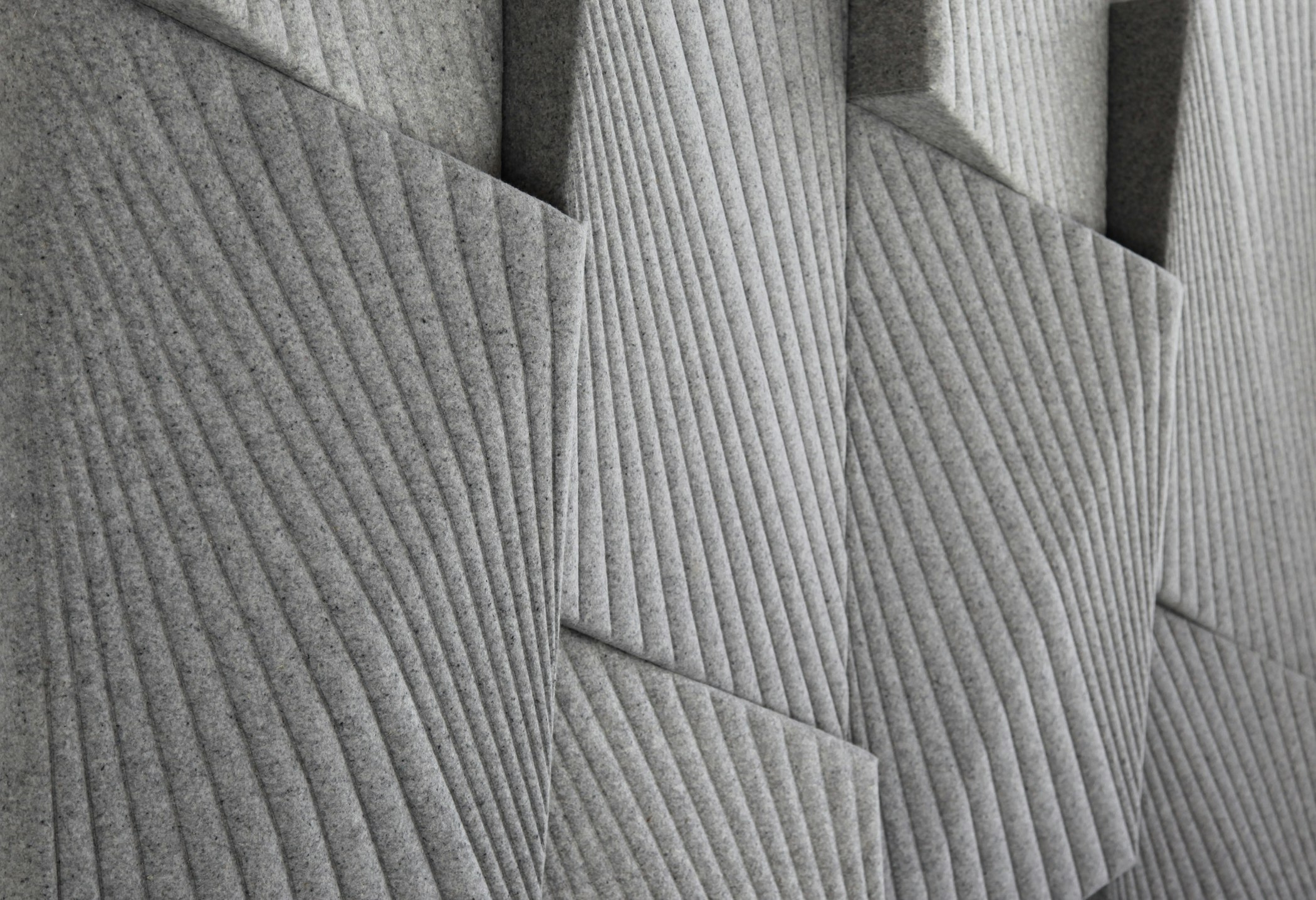

The last project discussed here, Wes McGee, Tsz Yan Ng, and Asa Peller’s Hard + Soft: Robotic Needle Felting for Nonwoven Textiles, probes an underexploited blind spot between a traditional technique, and its 19th-century industrial manufacturing adaptation. Traditional hand felting enabled control over varying thickness and density of the nonwoven fiber material, whereas mechanized felting was limited to producing a continuous roll of homogeneous single-thickness web material. It would take 21st-century technology for the researchers to fill this void in production by developing the hardware (process tooling) and software (digital workflow) capacity for additive manufacturing robotic felting processes.[4] Not only does their work combine the advantages of hand felting (nimble control over the material) with those of automated production (speed, consistency of the rate and force of needle punching), it also allows for a three-dimensional output. By controlling the direction and speed of punching synchronously with the motion of the machine, the material can be layered variably across a pre-formed substrate allowing for local differentiation in stiffness and density [Fig. 14]. Since nonwoven textiles make up half of the global textile market, a range of possible applications usefully complements the development of this technology and the context of the Research Through Making grants prioritizes architectural ones. McGee, Ng and Peeler’s prototypes offer the possibility for new felt surfacing strategies providing tactile effects, thermal insulation, and highly customized acoustic absorption [Fig. 15]. They look at furniture and wall-surfaces as sites to be lined and, after developing beautiful cushiony objects, turn to the felt acoustic tile [Fig. 16].

A range of traditional techniques in felt tape application (shiplapping, shingling, quilting, along with stiffening methods) reveals a wide range of desired options [Fig. 17]. For example, the shiplap technique offers speed, durability, and a high degree of formal variation while the shingle technique provides surface texture, depth and maximized sound absorption. The researchers aimed to develop a complex felting process rather than a product, leaving their prototypes free of geographic specificity and delegating cultural appropriation to designers worldwide. While their prototypes offer a clear demonstration of 2020’s tectonics, it may be difficult to situate them culturally other than in globalized high-tech aesthetics [fig. 18]. Yet, the exhibited assembly of soft panels offer a potential environment reminiscent of Joseph Beuys' Plight (1985). In this installation, a thermometer is placed on a blackboard with empty musical staves, which itself sits on a closed piano. These three items are situated at the center of a small space, lined from floor to ceiling in a heavy thickness of dense felt, isolating the room from the outside world, both thermally and acoustically. To enter this haven is to leave the context in which it is located, detaching the space from its geo-localization in favor of an inward focus on one’s body bathed in warmth and silence. The specificity of a site, as we saw earlier, can range from the geographical to the corporal, from the cultural to the atmospheric. Silence has been a serious contender in the search for universal phenomena, and as architects interested in phenomenology have shown, authentically universal and timeless designs are intrinsically of their place and time.

[Fig. 14] Robotic felter laying 1 ½ in. wide wool stripes with variable overlap for shiplap technique © Wes McGee, Tsz Yan Ng, and Asa Peller

[Fig. 15] Overview of exhibition at Liberty Research Annex, Taubman College, University of Michigan. From left to right, samples of composite felt test, 2 ft X 4 ft acoustic panels, video footage of various robotic felting processes, and foreground, bench with felted surface © Wes McGee, Tsz Yan Ng, and Asa Peller

[Fig. 16] Quilted acoustic panels © Wes McGee, Tsz Yan Ng, and Asa Peller

[Fig. 17] 2 ft × 6 ft acoustic panels with shingle and shiplap techniques © Wes McGee, Tsz Yan Ng, and Asa Peller

[Fig. 18] Approximately 2 ft × 2 ft complex surface poof with gray industrial felt strips shiplapped © Wes McGee, Tsz Yan Ng, and Asa Peller